Tel: +86 -18159244550 Email: jony@jyfire.com.cn

What Are You Looking For?

What Are You Looking For?

Tel: +86 -18159244550 Email: jony@jyfire.com.cn

The grooved rigid pipe coupling is an efficient and reliable solution for connecting large-diameter pipes in modern fire protection engineering. Its core value lies in providing stable and firm structural support.

Material :

Ductile IronNormal Diameter :

DN25 to DN300Working Pressure :

300 PSICertificate :

UL FMApplication :

Industrial Process,Fire Protection etc.MOQ :

200 PiecesDelivery Time :

15~45 DaysEmail : jony@jyfire.com.cn

Product Introduction

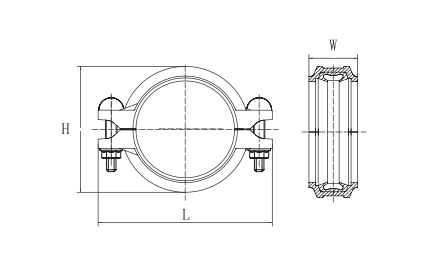

The sealing rubber ring is wound around the ends of the two connected pipes during assembly to form an initial seal.

The two-piece clamp is sleeved on the outside of the sealing ring, and the protruding part of its inner edge will precisely fit into the annular groove at the end of the pipe.

The bolts and nuts are tightened by evenly tightening the bolts to pull the two clamps together. This action will simultaneously compress the sealing ring to enhance the seal and mechanically interlock the raised part of the clamp with the pipe groove, thereby completely preventing the pipe from being pulled apart or rotated.

The grooved rigid coupling is a specialized component for mechanical connection of pipes. It forms a rigid, weld-like stable connection between the ends of pipes that have been pre-machined with annular grooves through clamps, gaskets and bolts. It is widely used in systems such as fire protection and industry where high stability of pipelines is required.

Product Features

• After connection, relative movement is not allowed to form a rigid coupling system.

• Compared with traditional welding or flange connection, its installation is faster and safer (no hot work is required), and it is also convenient for later system maintenance and renovation.

• The "heel" structure on the inner edge of the clamp will be deeply inserted into the pipe groove to achieve mechanical locking.

Product Parameter

| Norminal Size | DN25-DN32-DN40-DN50-DN65-DN80-DN100-DN125-DN150-DN200-DN-250-DN300 |

| Main Material | Ductile Iron |

| Bolt&nut Material | Carbon Steel |

| Gasket Material | EPDM, nitrile, silicone rubber, etc. |

| Working Pressure | 300 PSI |

| Surface | Red Painting |

FAQ

Q:What’s the MOQ for grooved rigid coupling?

A:For standard sizes, our MOQ is usually 200 pieces. For large sizes or special requirements, the MOQ can be one unit. We are always willing to provide customers with flexible solutions.

Q:What is your payment terms?

A:Payment supports T/T, L/C, etc. We also support payment via wechat or Alipay.

Q:What is the delivery time?

A:The production usually takes 15 to 45 days. For large or special orders, it may take 60 days or longer. We will provide you with an accurate production plan after placing your order.

Contact Us

One Stop Solution for fire hoses,sprinklers,nozzles,valves and pipe fittings!

JINYUAN TECHNOLOGY DEVELOPMENT CO.,LTD

Tel.:86-18159244550 Mobil:18159244550

EMAIL:Jony@jyfire.com.cn

ADD:CHENGGONG TECHNOLOGY ZONE PHASE 3,XIMEI TOWN,NAN'AN QUANZHOU CITY

Hot Tags :

leave a message

Scan To Wechat :

Scan To WhatsApp :